Cryptocrystalline Magnesite Resource

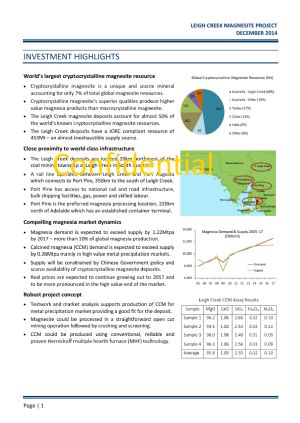

Sydney, Dec 15, 2014 AEST (ABN Newswire) - Leigh Creek is the World's largest cryptocrystalline magnesite resource

- Cryptocrystalline magnesite is a unique and scarce mineral accounting for only 7% of total global magnesite resources.

- Cryptocrystalline magnesite's superior qualities produce higher value magnesia products than macrocrystalline magnesite.

- The Leigh Creek magnesite deposits account for almost 50% of the world's known cryptocrystalline magnesite resources.

- The Leigh Creek deposits have a JORC compliant resource of 453Mt - an almost inexhaustible supply source.

Close proximity to world class infrastructure

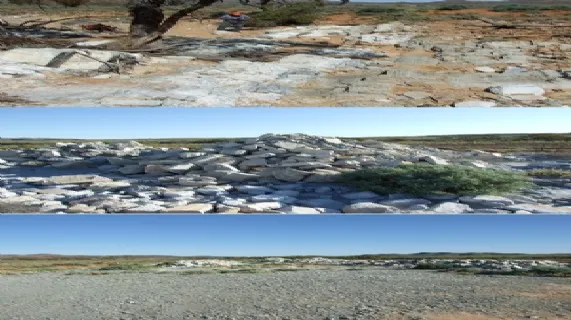

- The Leigh Creek deposits are located 20km northwest of the coal mining township of Leigh Creek in South Australia.

- A rail line operates between Leigh Creek and Port Augusta which connects to Port Pire, 350km to the south of Leigh Creek.

- Port Pirie has access to national rail and road infrastructure, bulk shipping facilities, gas, power and skilled labour.

- Port Pirie is the preferred magnesia processing location, 220km north of Adelaide which has an established container terminal.

Compelling magnesia market dynamics

- Magnesia demand is expected to exceed supply by 1.22Mtpa by 2017 - more than 10% of global magnesia production.

- Calcined magnesia (CCM) demand is expected to exceed supply by 0.26Mtpa mainly in high value metal precipitation markets.

- Supply will be constrained by Chinese Government policy and scarce availability of cryptocrystalline magnesite deposits.

- Real prices are expected to continue growing out to 2017 and to be more pronounced in the high value end of the market.

Robust project concept

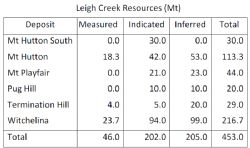

- Testwork and market analysis supports production of CCM for metal precipitation market providing a good fit for the deposit.

- Magnesite could be processed in a straightforward open cut mining operation followed by crushing and screening.

- CCM could be produced using conventional, reliable and proven Herreshoff multiple hearth furnace (MHF) technology.

OVERVIEW

Location

- The Leigh Creek deposits commence 20km northwest of the coal mining town of Leigh Creek.

- The deposits extend northwest for over 100km from the Northern Flinders Ranges into the Willouran Ranges.

- Leigh Creek is located 260km north of Port Augusta and 350km north of Port Pirie.

- Leigh Creek is connected to Port Augusta and Port Pirie by a standard gauge rail line and all weather bitumen roads.

- Port Pirie has access to bulk shipping facilities, national rail and road infrastructure, natural gas, power and skilled labour.

- Port Pirie is 220km north of Adelaide, the capital city of South Australia which has access to container shipping facilities.

History

- Magnesite has been mined in the Leigh Creek region on an irregular and small scale basis since the early 1900's.

- In the late 1990's, significant exploration and other study work was undertaken to develop a magnesium metal project based on the deposits.

Tenements

- Leigh Creek Magnesite Pty Ltd owns Exploration Licence EL 4567 Termination Hill and EL 4729 Witchelina.

- EL 4567 covers an area of 542km2 and includes the Mount Hutton South, Mount Hutton, Mount Playfair, Pug Hill and Termination Hill magnesite deposits.

- EL 4729 covers an area of 452km2 and includes the Witchelina magnesite deposit.

Resources

- The due diligence for the magnesium metal project included significant exploration, environmental, trial mining and metallurgical studies.

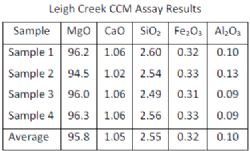

- The project did not proceed but the exploration work identified a JORC compliant resource of 453Mt grading 40-43% MgO, making the Leigh Creek magnesite deposits the largest known cryptocrystalline magnesite resource in the world.

MAGNESIA INDUSTRY

Magnesia (magnesium oxide or MgO) characteristics

- A specialist industrial mineral with diverse markets.

- Produced from magnesite or from seawater/brines.

- High melting point of 2852°C/5,166°F.

- Physically and chemically stable at high temperatures.

- Reactive in its calcined form.

- An alkali.

- A nutrient.

Magnesia products

- Calcined magnesia (CCM) produced at 800-1,100°C.

- Deadburned magnesia (DBM) produced at 1,500-2,200°C.

- Electrofused magnesia (EFM) produced at > 2,800°C.

Magnesia applications

- DBM and EFM used predominantly in refractory applications:

- Linings for high temperature furnaces in steel, cement, non ferrous, glass and chemical industries.

- DBM also used in welding flux applications.

- EFM also used in electrical insulation applications.

- CCM used mainly in chemical applications:

- Metal precipitation in nickel, cobalt, uranium and rare earths.

- Plant and animal nutrition.

- Waste and water treatment.

- Iron and steel fluxing.

- Pulp and paper and cellulose production.

- Flame retardants.

- Construction and general chemicals.

Magnesia market

- Magnesia demand was 10.55Mt in 2012 and is expected to grow at 3.6% pa out to 2017 to 12.61Mt an increase of 2.06Mt.

- Growth will be strongest in high value CCM metal precipitation, waste and water treatment and flame retardant applications.

- Announced capacity additions out to 2017 are 0.84Mt or 1.22Mt less than demand.

- Supply growth will be constrained by Chinese Government policy and limited availability of cryptocrystalline magnesite.

- Excess demand will continue to place upward pressure on prices particularly in strong growth, high value applications.

To view figures and diagrams and data sheet, please visit:

http://media.abnnewswire.net/media/en/docs/78927-LeighCreekMagnesite.pdf

Contact

David Ward

Director and Representative

Transaction Advisory Services

Ernst & Young

Level 51, 111 Eagle St

Brisbane QLD 4000

Tel: +61 7 3011 3270

Mobile: 0413 758 197

Email: david.ward@au.ey.com

Anuk Manchanda

Manager

Transaction Advisory Services

Ernst & Young

Level 51, 111 Eagle St

Brisbane QLD 4000

Tel: +61 7 3243 3784

Mobile: 0434 087 673

Email: anuk.manchanda@au.ey.com

| ||

|